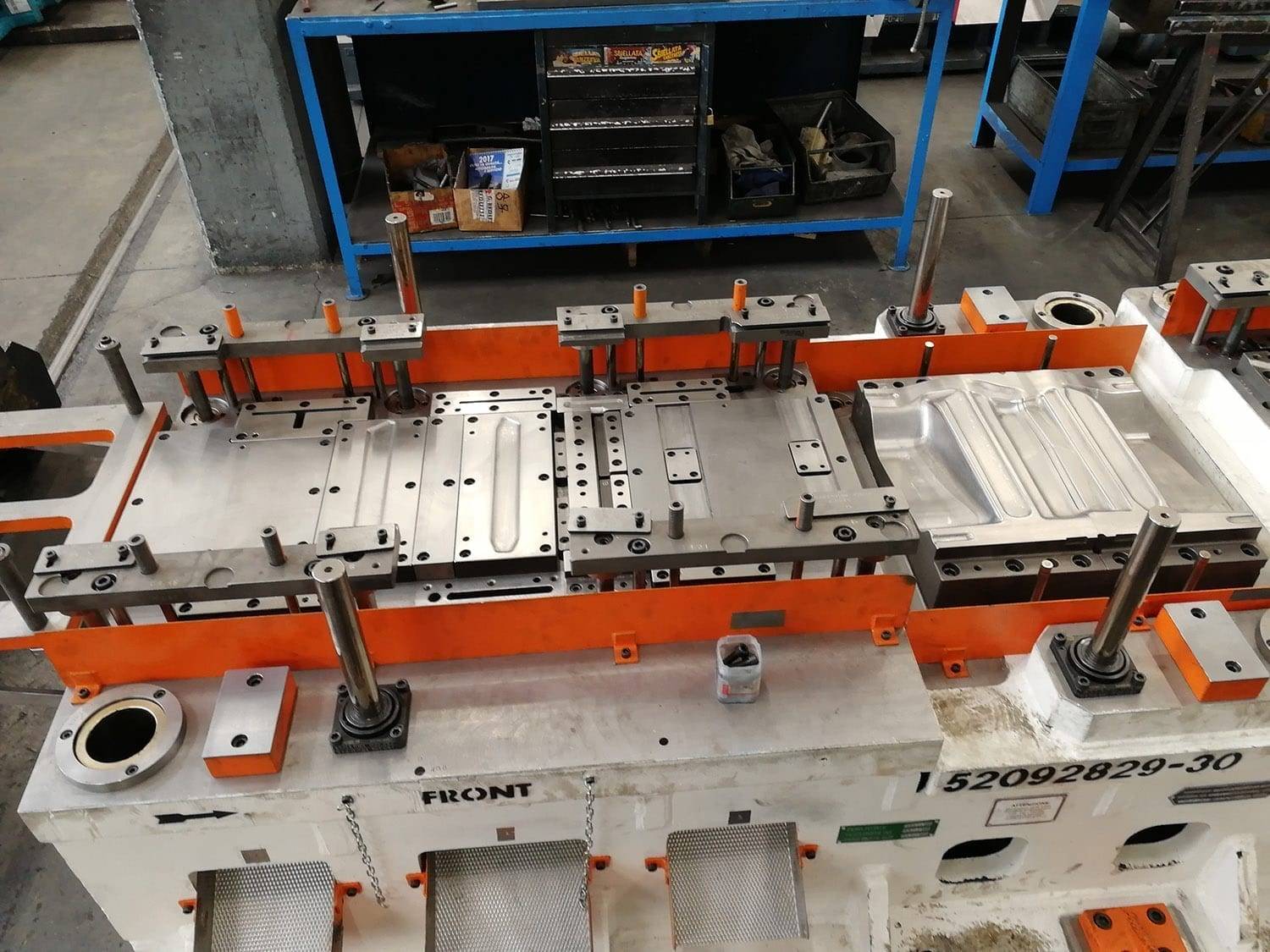

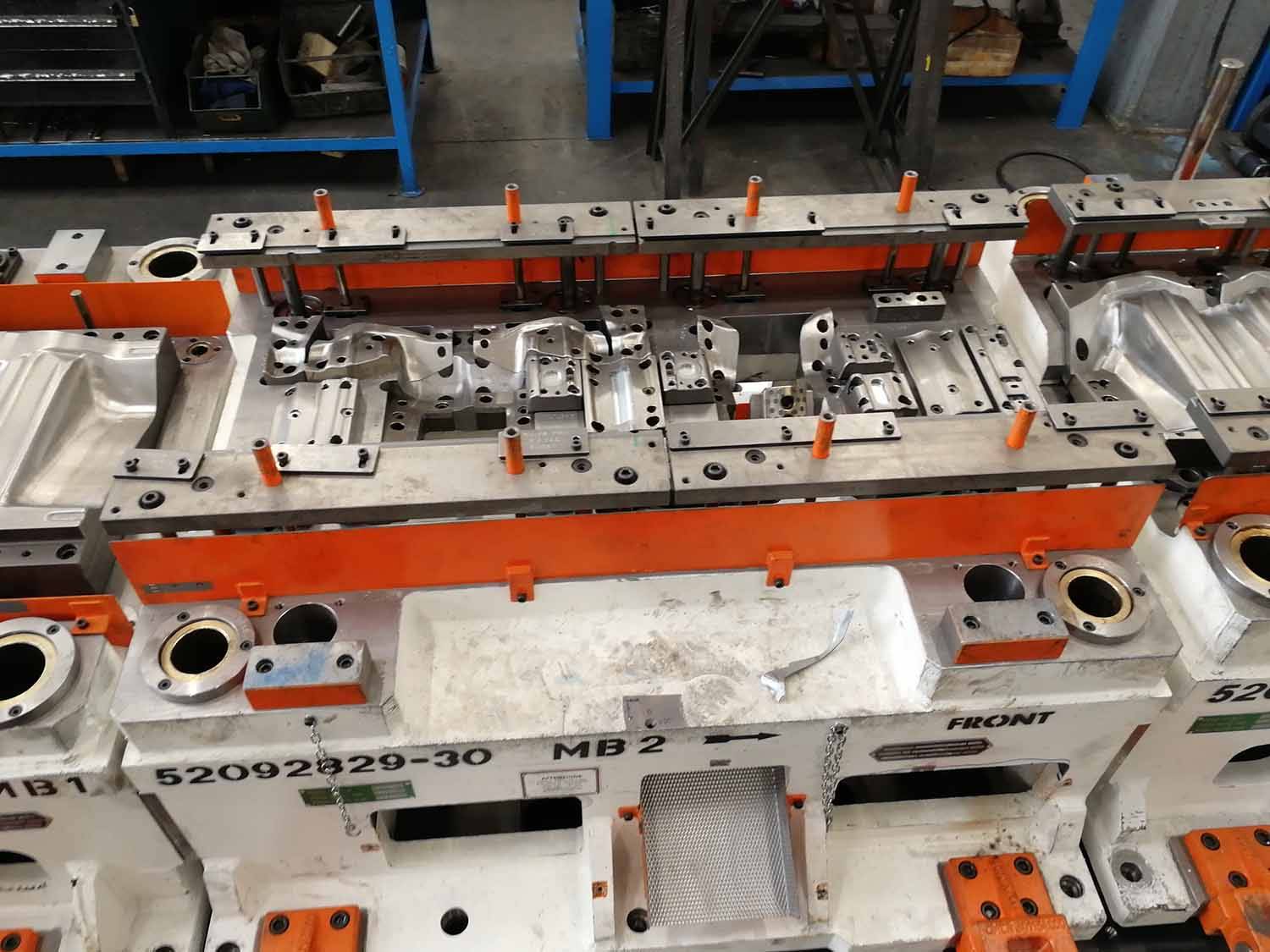

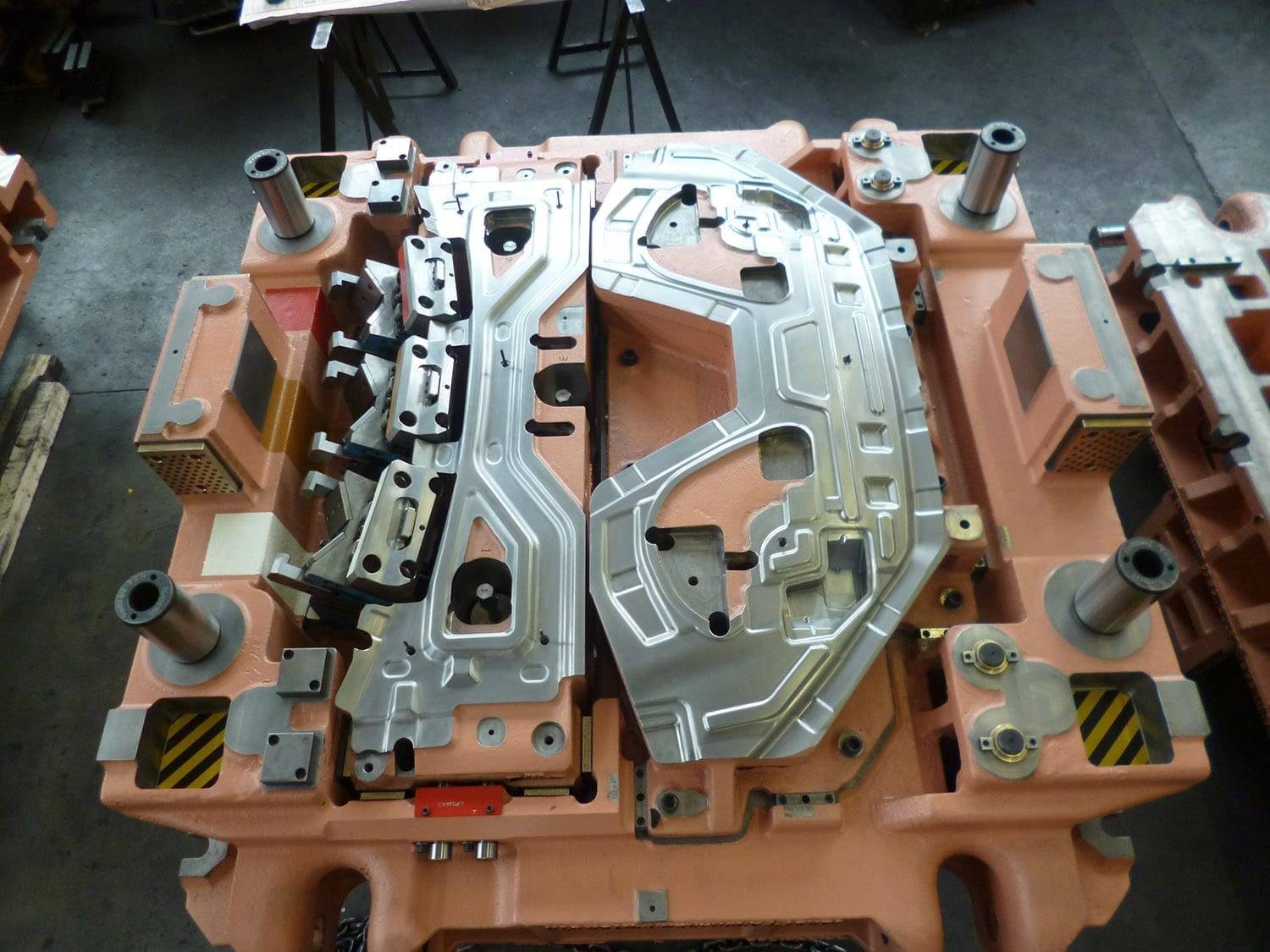

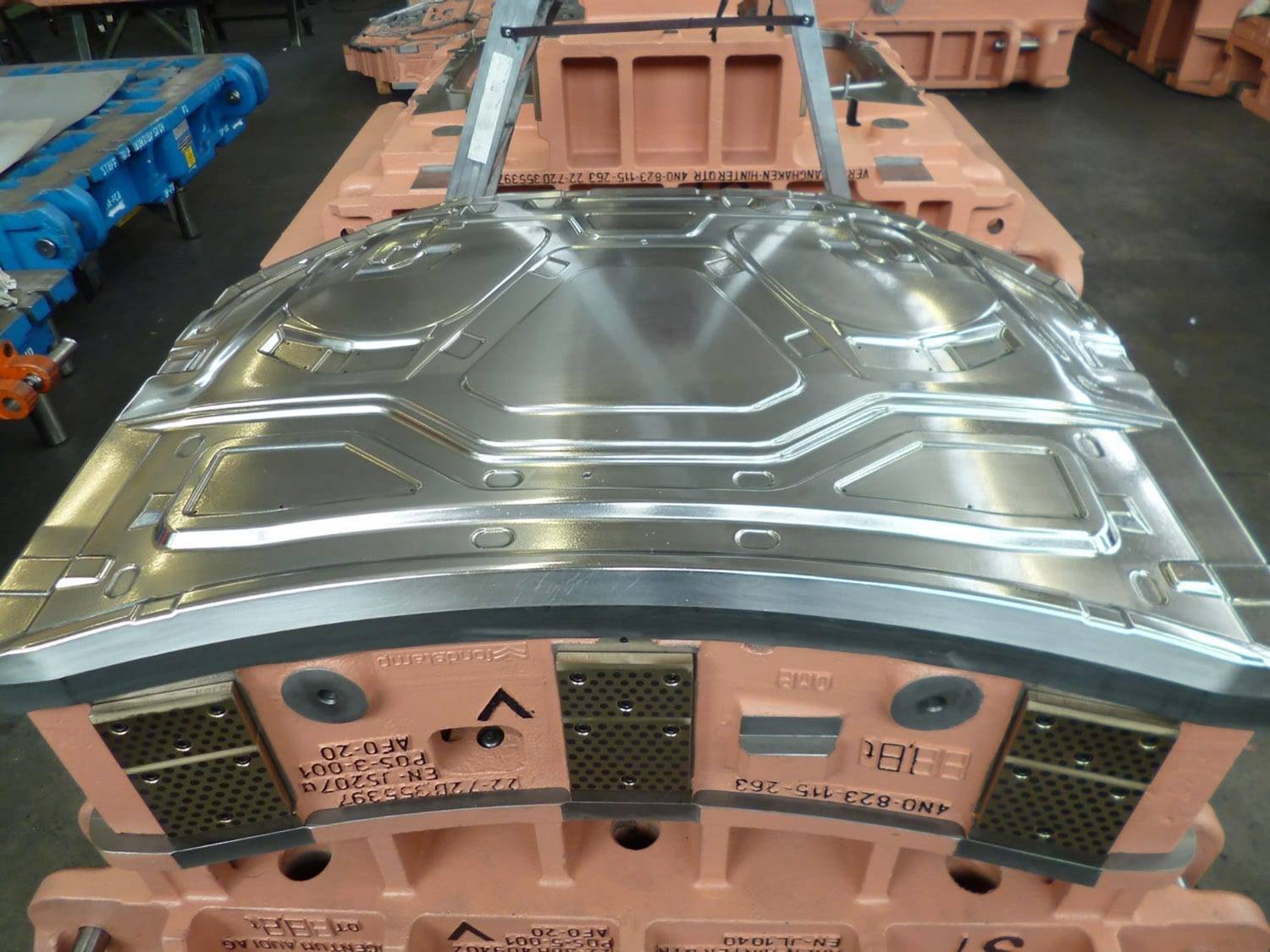

Progressive pitch moulds

Progressive pitch moulds are used to produce large quantities of components, therefore working at high rates. They allow the finished product to be produced with a single mould, giving the best performance in terms of product quality, speed and production price.

For information on this type of moulds, or to request a free, no-obligation quotation, please fill in the appropriate form in the contact section of this website.

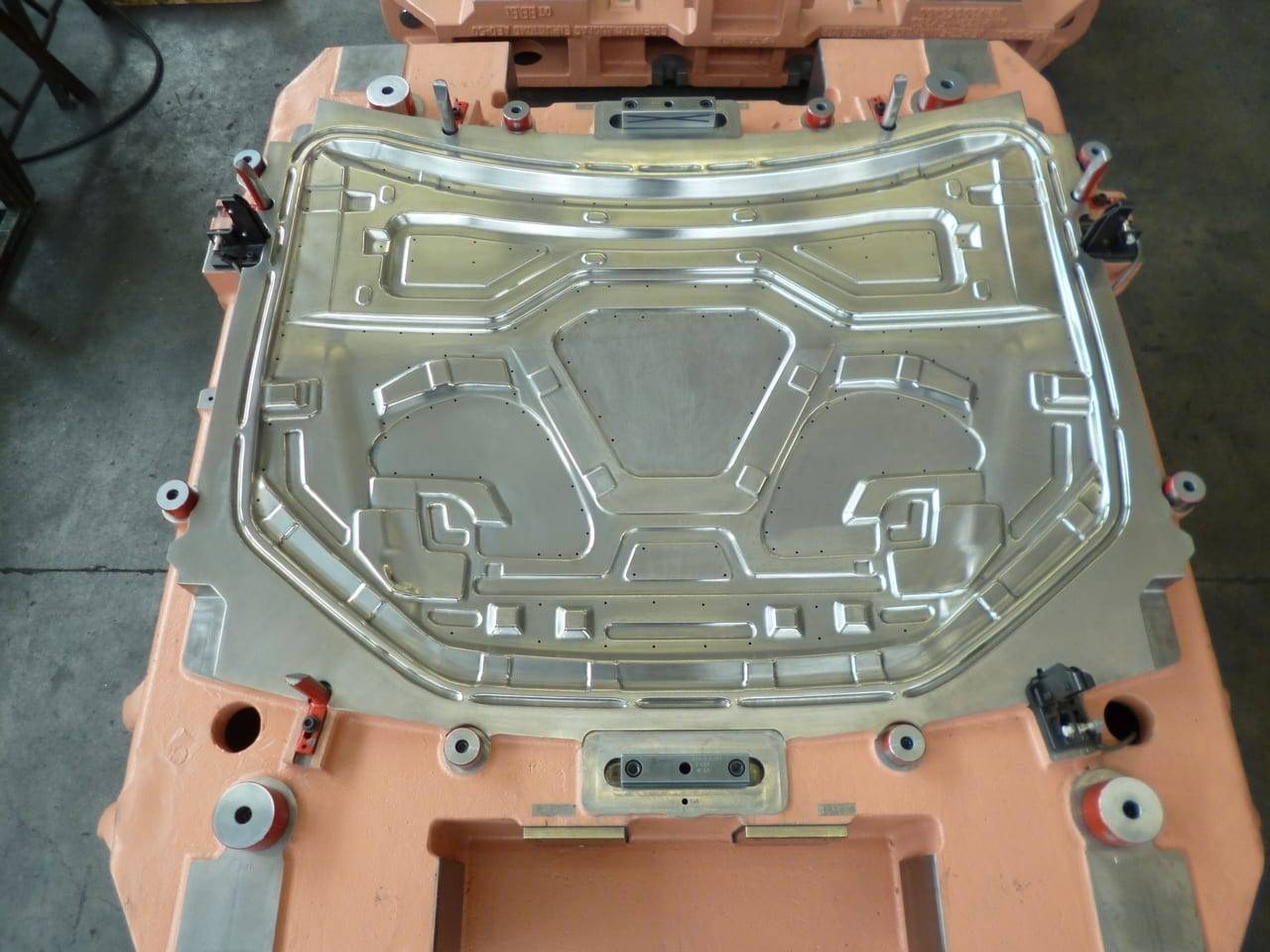

The progressive mould is a particular type of mould that allows you to obtain a well-defined product with successive processing stages; starting from a sheet of metal, the product is cold-formed through shearing, drilling, drawing and bending operations. The part only comes off the mould at the end of the production process.

Progressive dies work at very high rates and are therefore usually chosen to produce large quantities of components. The use of a single mould allows excellent results in terms of both production speed and economic cost, guaranteeing a reduced cost for each individual part.

This particular type of mould can be used on different types of presses, optimising the workshop's production processes.

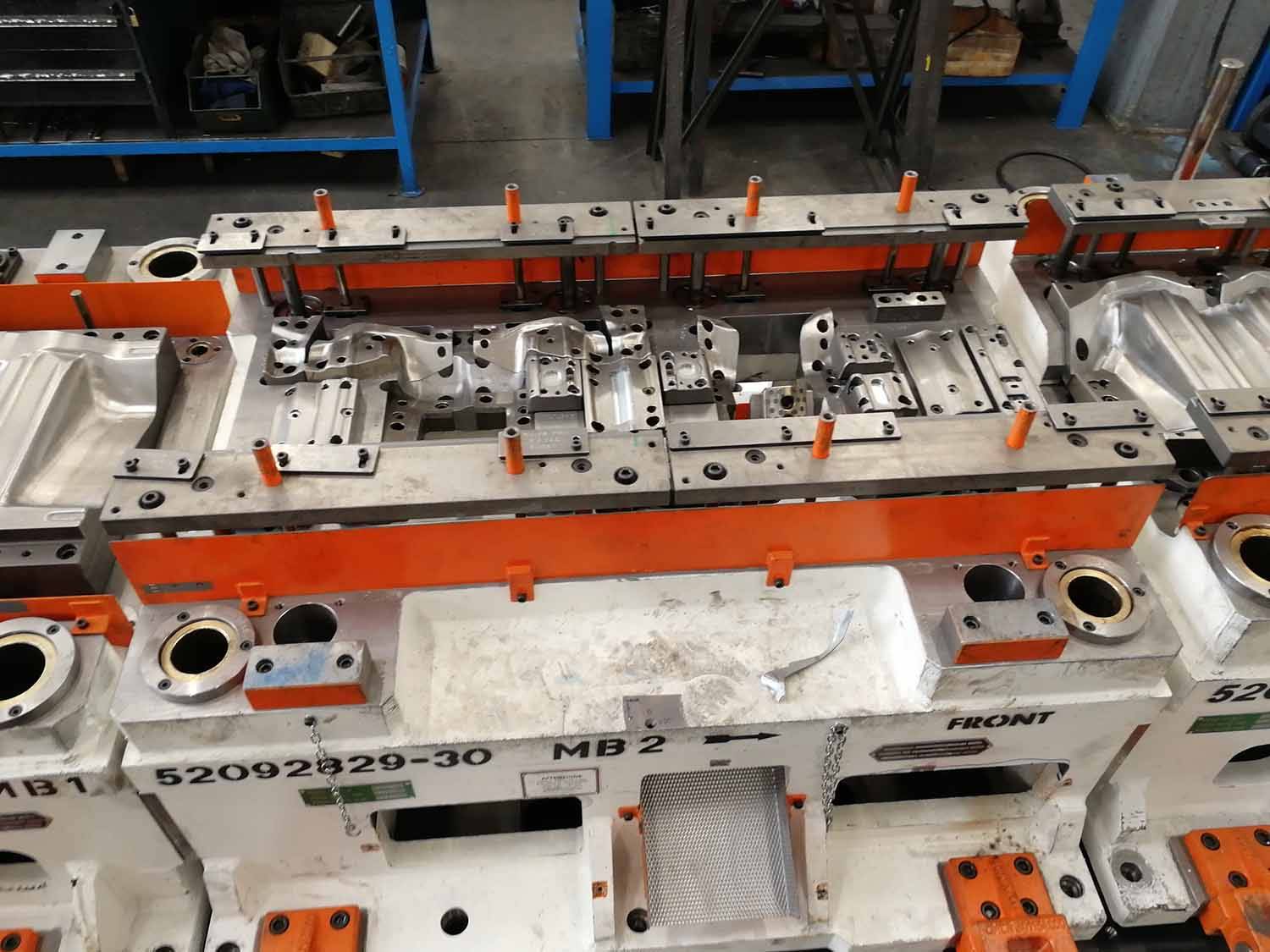

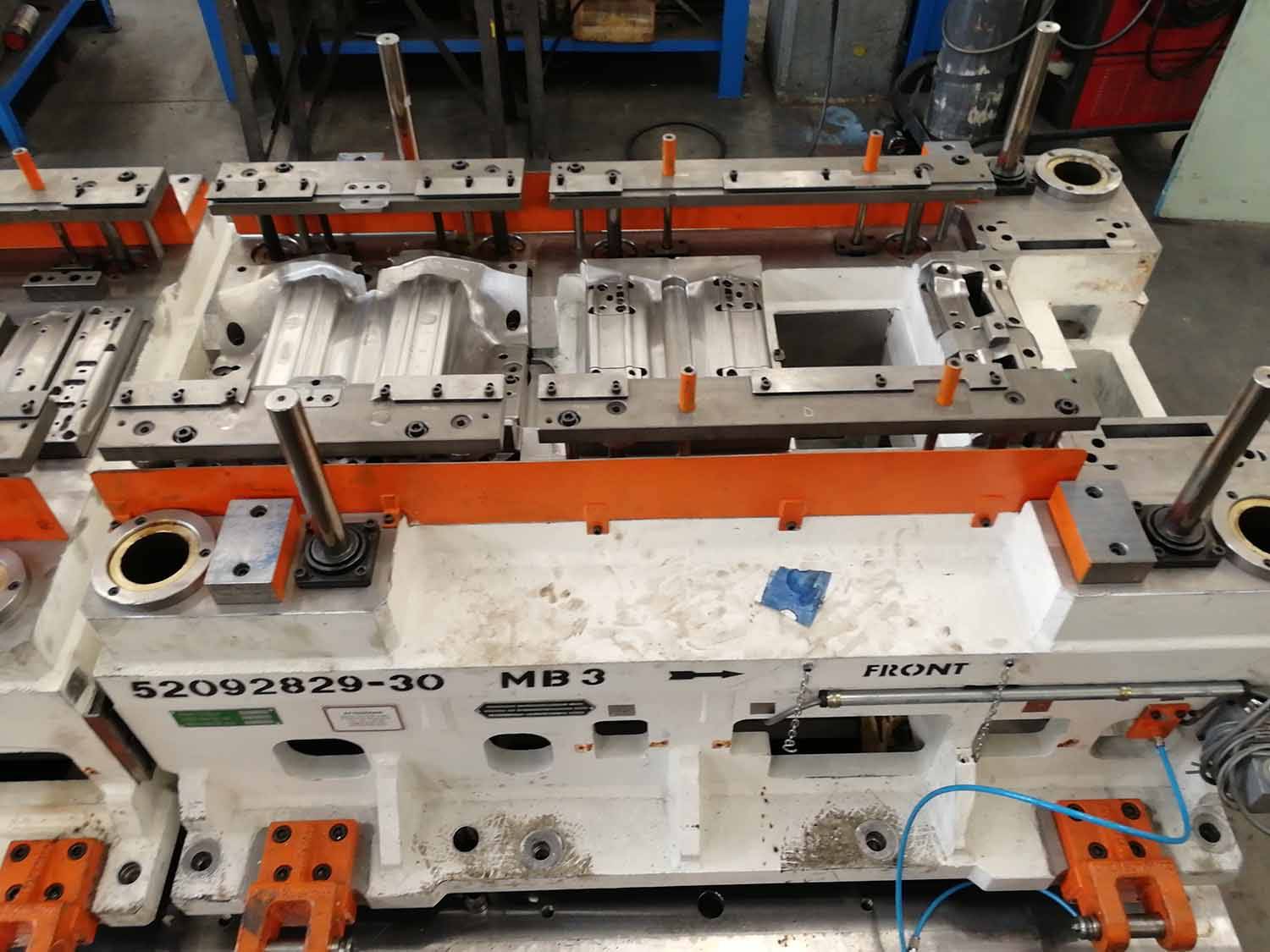

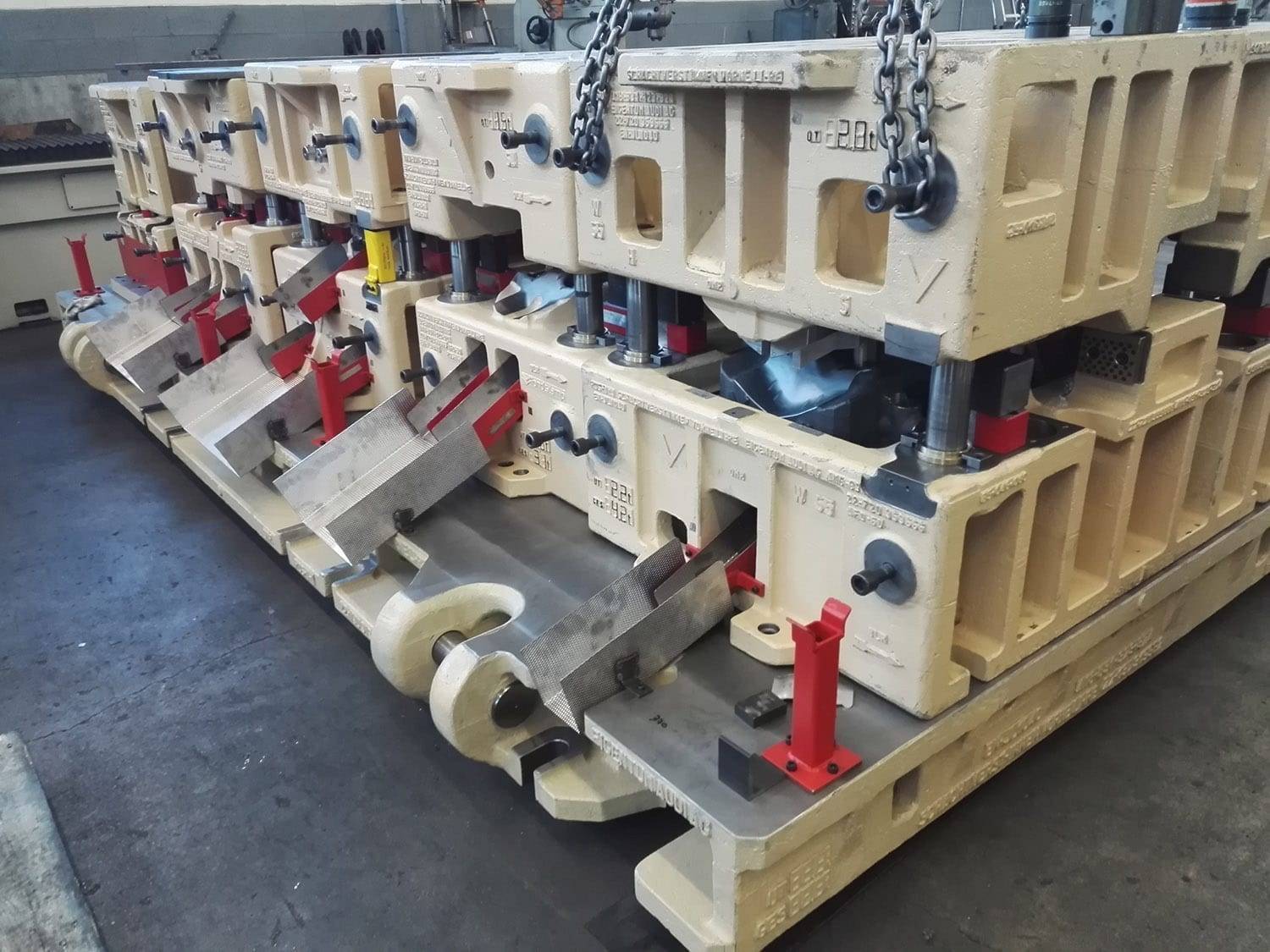

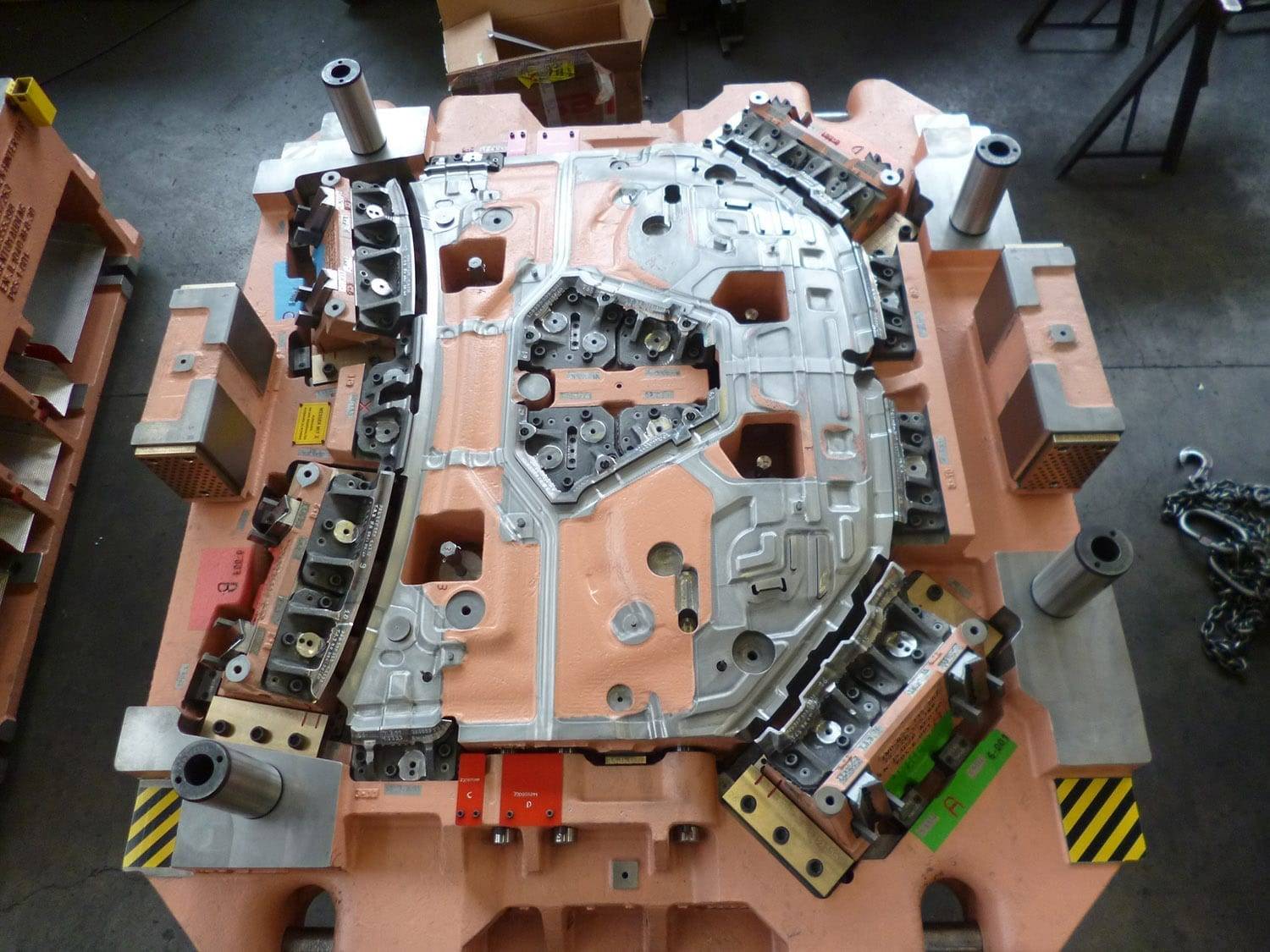

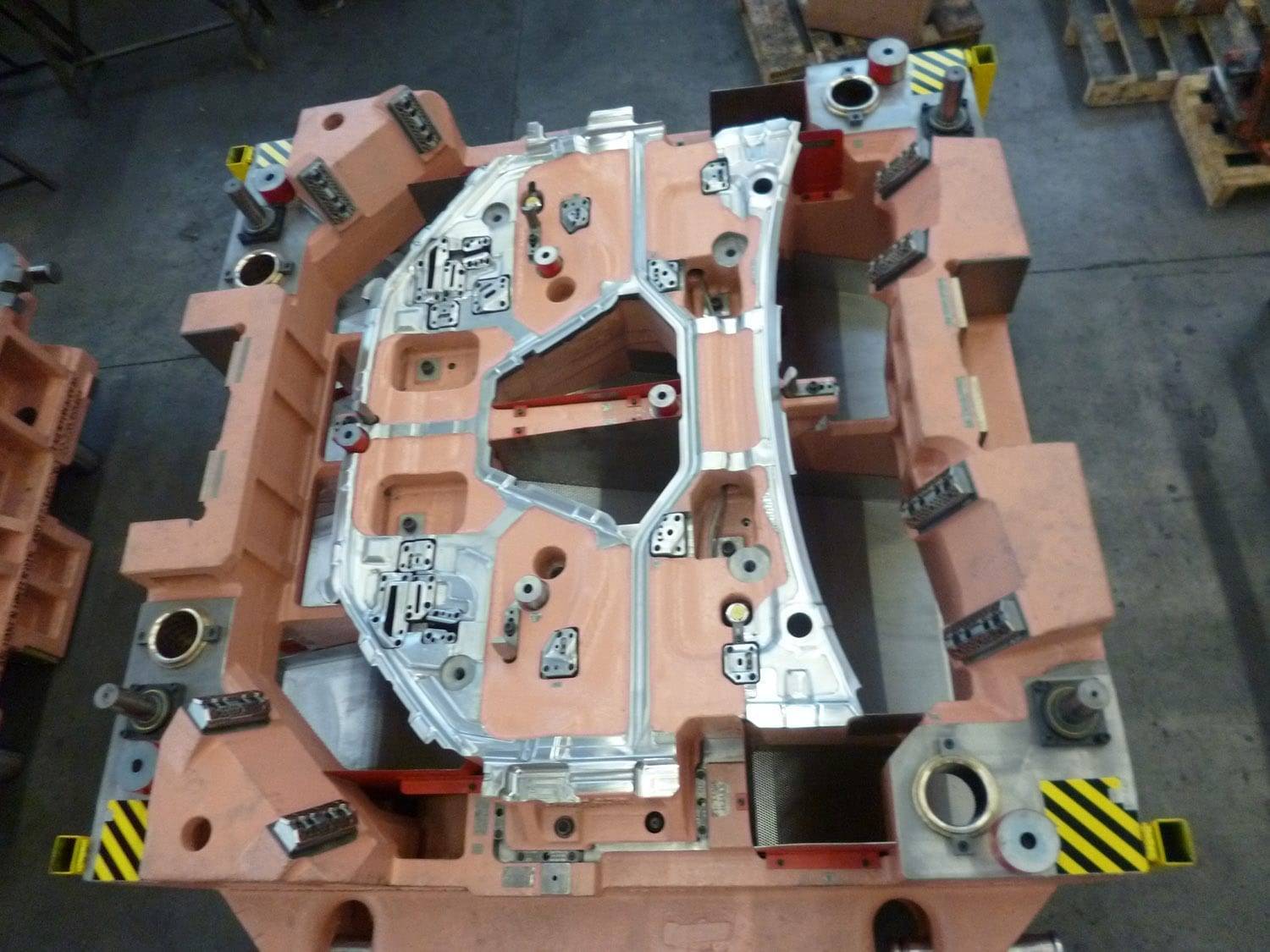

Transferred piece moulds

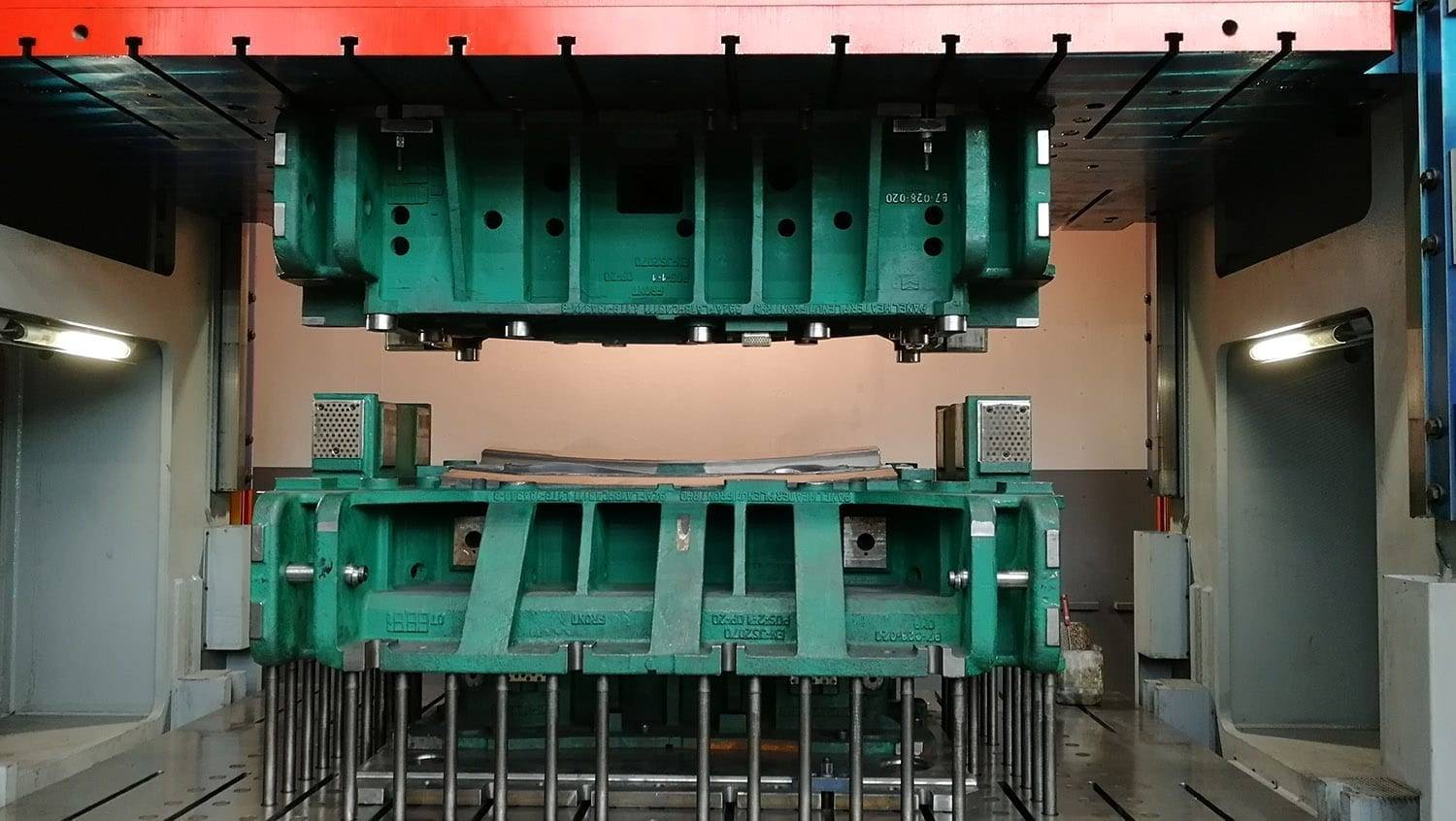

The transfer mould allows the production of parts that require several operations on a single machine. It works at lower rates than the progressive die, because the parts are transferred from one operation to the next by means of a piece of equipment outside the die called a transfer.

OMP Perego benefits from decades of experience in proposing simple solutions for complex moulds. Ask us for a quote, free of charge and without obligation.

Transfer moulds allow greater processing freedom than progressive dies, as they are not constrained by the use of a single mould. Products are transferred unfinished through the use of manipulators or synchronised transfer bars, with two or three axes. The transfer mechanism is not part of the mould, which makes its use rather constraining, but still ensures the possibility of producing parts that require several machining operations on a single machine. Generally, this type of mould has the possibility of producing more aesthetically finished products at a slightly higher cost.

This type of mould is made to produce parts with specific technical and aesthetic requirements, allowing the company to carry out machining that would not be possible with a simple progressive mould.

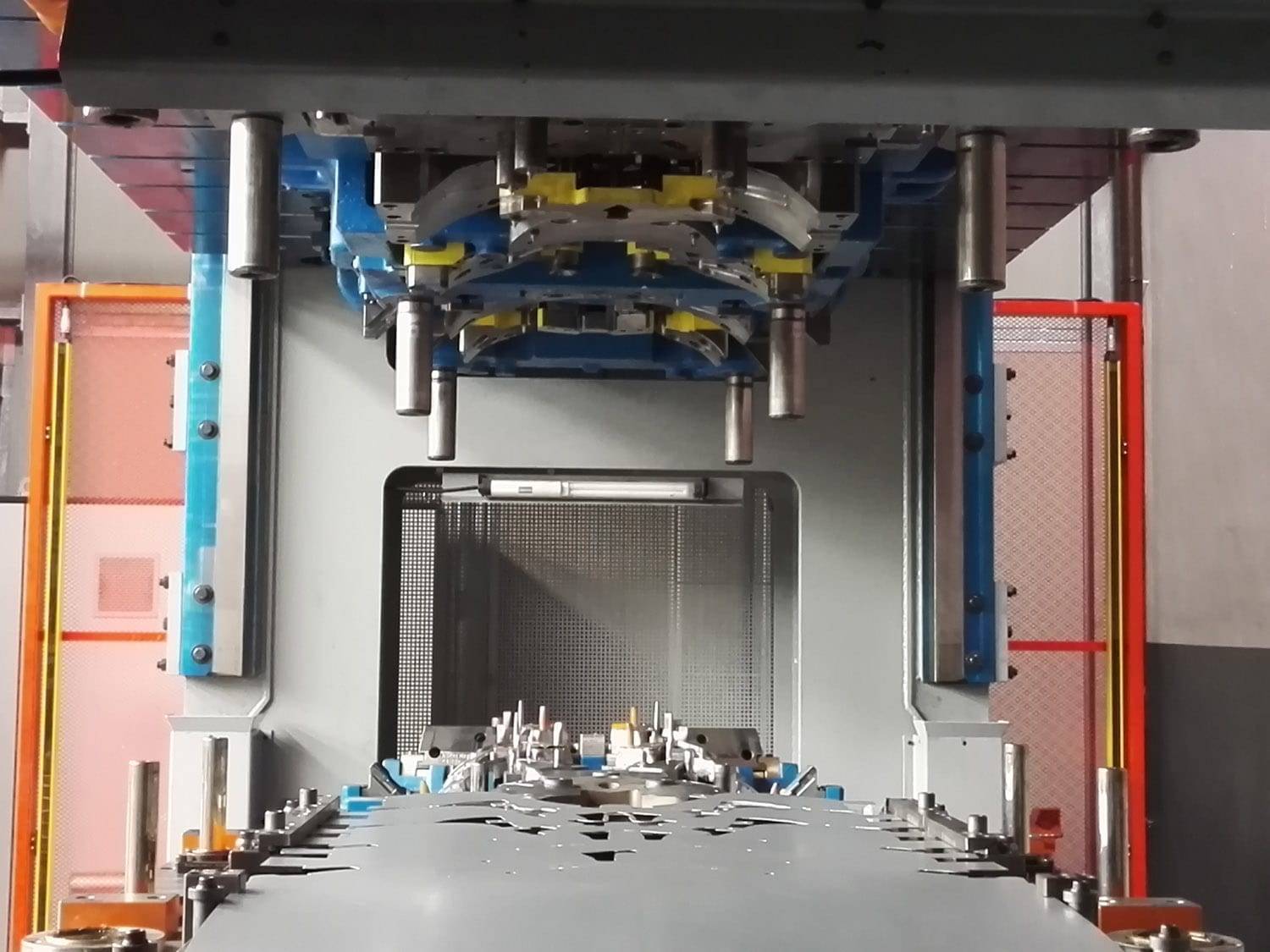

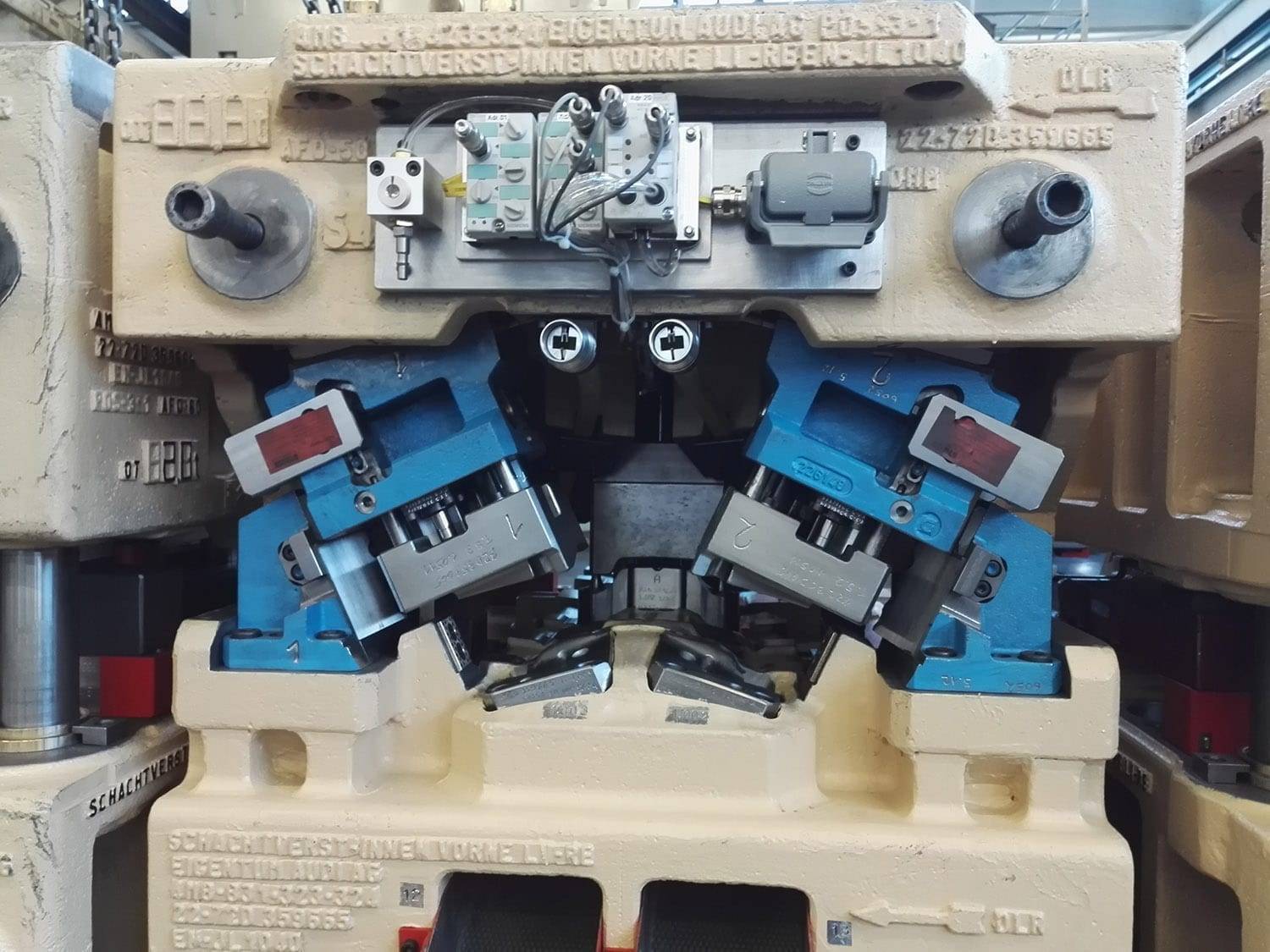

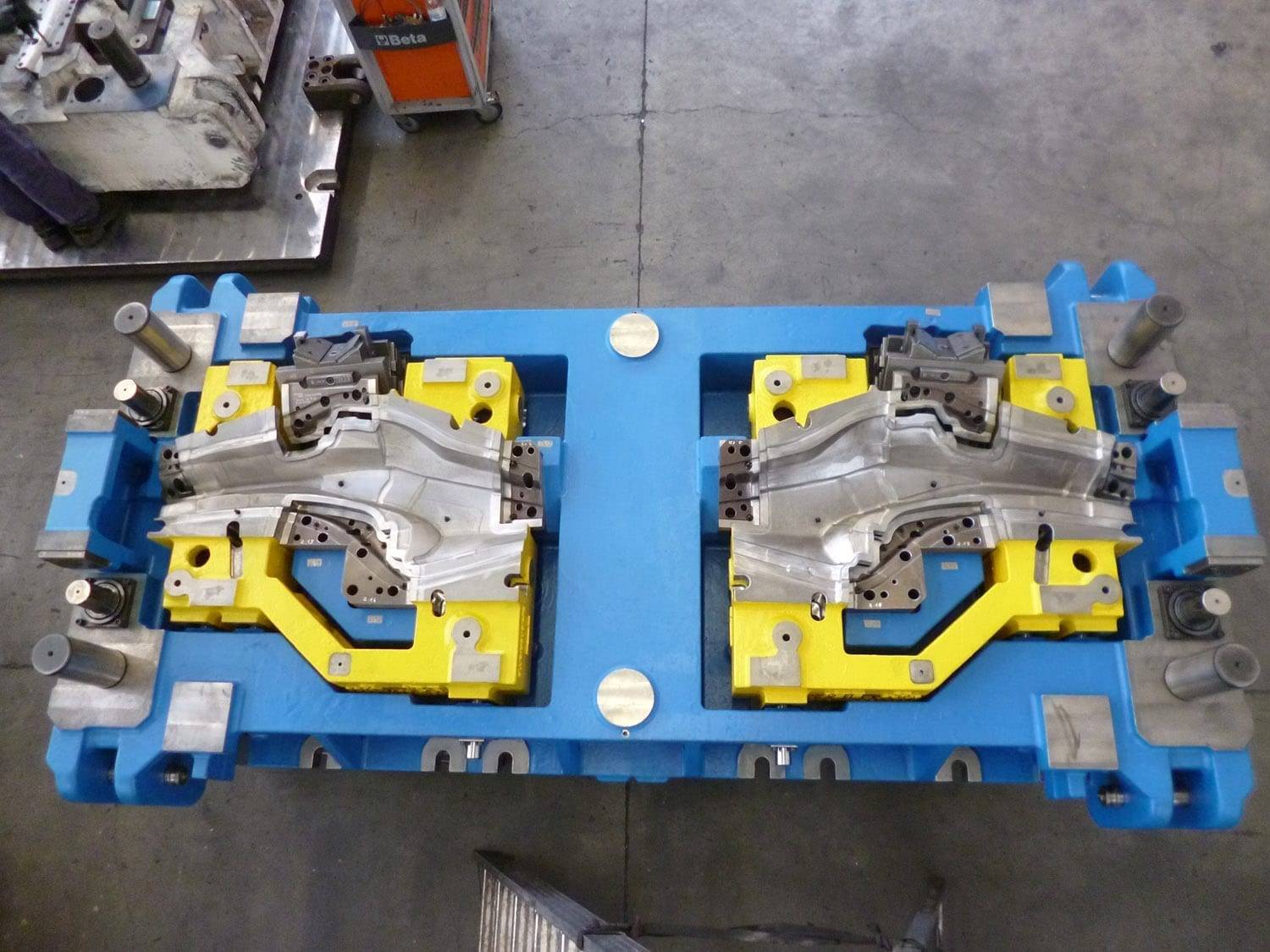

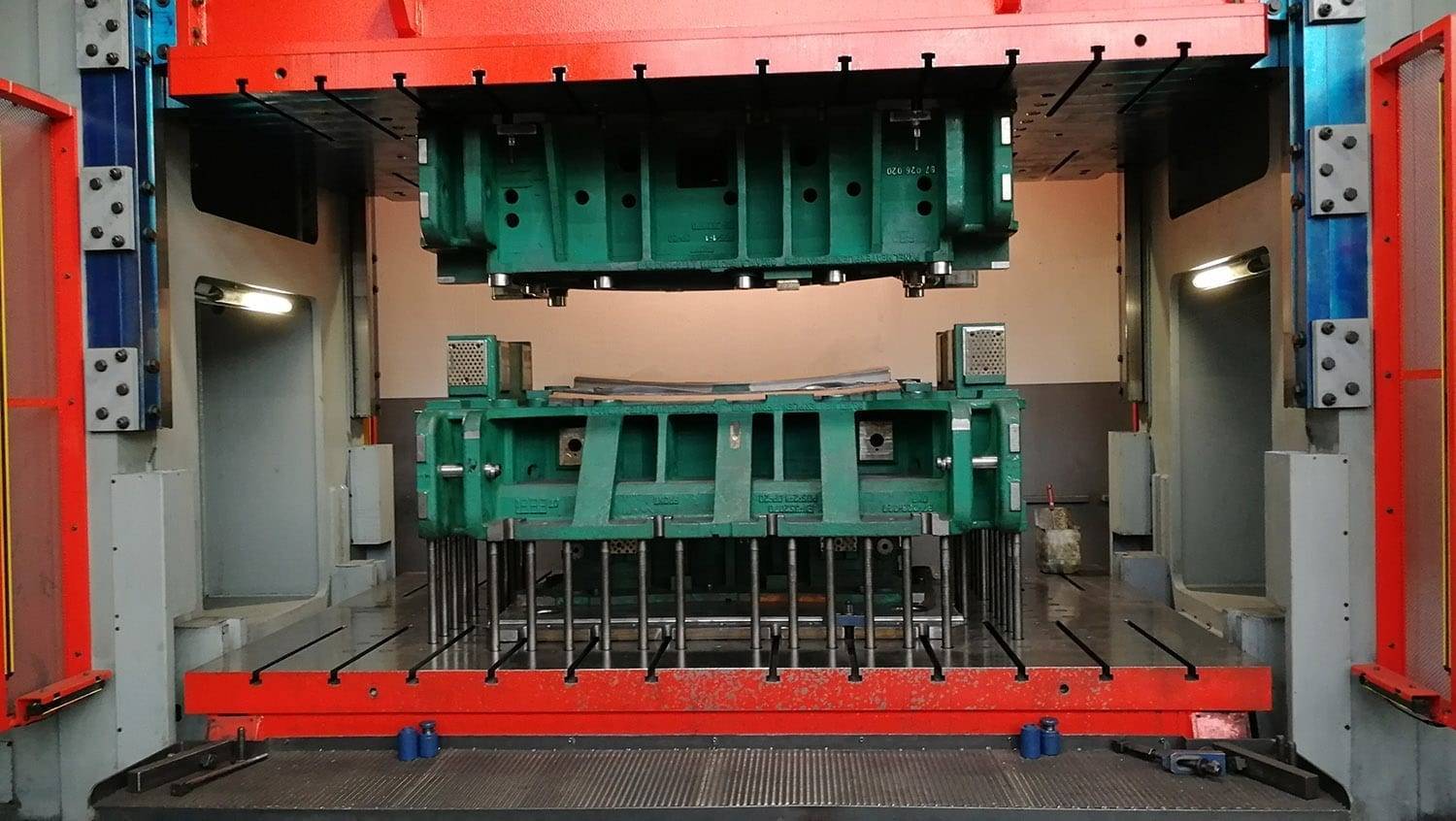

Moulds for robotic presses

OMP Perego designs and produces moulds for robotic press lines, taking advantage of decades of experience in the sector and the company's know-how. Ask us for information and a consultation - free of charge and without obligation - to design together the ideal moulds for your presses. Contact us via the appropriate section of this website and we will get back to you as soon as possible.

Robotic press lines are those particular types of plants whose products are moved by means of mechanical robots. Unlike the other two types of presses. In this case, the robots connect different moulds on different machines, creating a single production process capable of delivering extremely complex finished products.

OMP Perego is able to conceive, design and build any mould for this type of robotic press line, offering proactive and qualified support for all companies that need it.